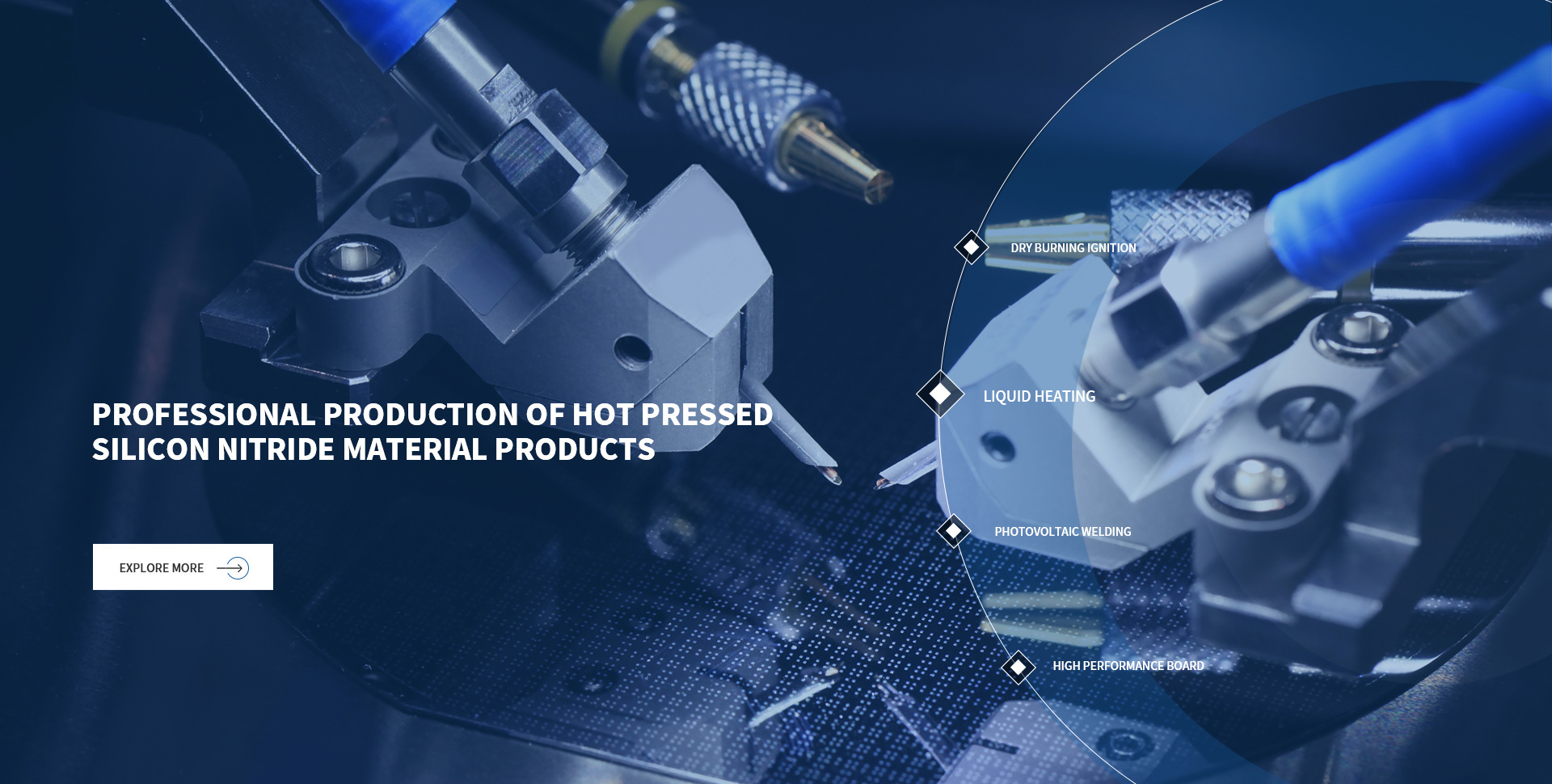

PRODUCT DISPLAY

Product display

ABOUT

About Us

Guangzhou Shi Chao

special ceramics manufacturing co ltd

Abbreviation: Guangzhou Shi Chao

Stock code: 19145955-0

Established in 1992

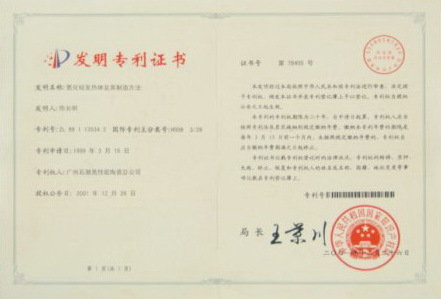

Located in Panyu District, Guangzhou City, Guangdong Province, it is a high-tech enterprise specializing in R & D, production and sales of hot-pressed silicon nitride materials. The company has 24 years of experience, skilled and professional. The products cover liquid silicon nitride heating plate, dry point silicon nitride heating plate, vegetable oil furnace igniter, photovoltaic welding knife, ignition plug, silicon nitride ceramic body, etc. The company's products are mainly sold to all regions of the country, Japan, South Korea, Malaysia and other regions. We are committed to providing customers with high quality products, including technical strength with independent intellectual property rights, and are committed to providing customers with safe and reliable products and timely and thoughtful after-sales service.

-

Production advantages1. 20 years of independent research and development, with a relatively stable product structure and process 2. The technological process can be divided into simple processes, and certain processes can be appropriately merged and decomposed according to the requirements of the process synchronization. The formulas for each process are similar. 3. The product output is large enough, and the unit labor is large enough The main purpose of the assembly line production method is to ensure that the production process of the field frequency meets the requirements of continuity, balance, proportionality, and balance. High productivity, able to timely provide products with high market demand. Due to the use of specialized equipment and process equipment in professional production and assembly lines, as well as mechanized transportation devices, labor productivity can be improved. In other words, short production cycles, reduced work in progress and transportation workload, accelerated capital turnover, and reduced production line costs can also enhance production management work, promote enterprises to strengthen production technology preparation and production service work.LERAN MORE

-

Research and development advantagesResearch and development advantagesLERAN MORE

ADVANTAGE

Enterprise advantage

1, 20 years of independent research and development product structure and process is relatively stable. 2. The technological process can be divided into simple working procedures, and some working procedures can be properly combined and decomposed according to the requirements of working procedures at the same time. The formulas of each working procedure are similar. 3, the product output is large enough, the unit of labor is large enough. The main purpose of assembly line production mode is to make the production process of field frequency better meet the requirements of continuity, balance, proportionality and equilibrium. High productivity, can provide a large number of market demand products in a timely manner. Due to the use of special equipment and process equipment on professional production and assembly lines, as well as mechanized transportation devices, it can improve labor productivity, say short production cycles, reduce the amount of work-in-process and transportation workload, accelerate capital turnover, and reduce production line costs. It can also promote production management and promote enterprises to strengthen production technology preparations and production services.

R & D Advantage

GLOBAL REACH

Global Layout and Customers

Guangzhou Shichao Special Ceramics Manufacturing Co., Ltd. was established in 1992 and is located in Panyu District, Guangzhou City, Guangdong Province. It specializes in the production of hot-pressed silicon nitride material products. It has international leading, high-tech sintering technology and formula. It has independent innovation, research and development, A high-tech enterprise integrating production, sales and technical services. The products mainly cover liquid silicon nitride heating plate, dry point silicon nitride heating plate, vegetable oil furnace igniter, ignition plug, photovoltaic welding knife, silicon nitride ceramic body, etc. Products are sold throughout the country, South Korea, Japan, Malaysia and other regions.

Explore more

NEWS

Stone tide information